Wine transvasor

Wine transvasor

The MEC transvasor was imagined and designed inPont d‘Ain, in the heart of Cerdon, to offer winemakers and cooperatives an innovative bottling solution. The system was initially intended for sparking wine produced using ancestral methods but can be used for all wine types. Our new machine is notably used by producers of Cerdon and Clairette. It is also popular on export markets, such as the Netherlands and the United States.

For almost 30 years, MEC has grown by developing its activities of designing and building special machines.

The company has stood out by automating certain difficult wine making tasks that were traditionally carried out by hand. The quality of the systems designed, alongside the know-how of our experts, have made MEC a French benchmark in terms of conditioning lines for still or sparkling wines.

This close connection between wine producing regions and industrial innovation enables us to meet the needs of winemakers or merchants, with a unique machine: The transvasor.

What does a wine transvasor provide?

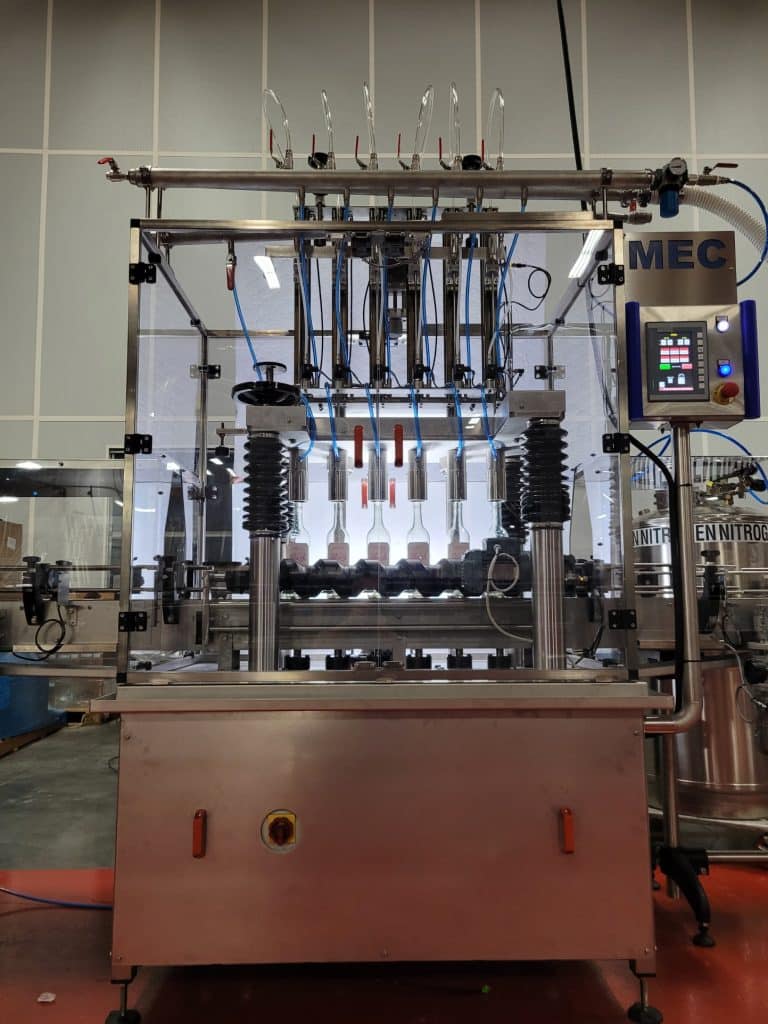

Without fuss, the transvasor can transfer a bottle of sparkling or still wine to a storage tank or its final bottle. The whole operation is done without loss of liquid or deterioration in quality.

Space savings

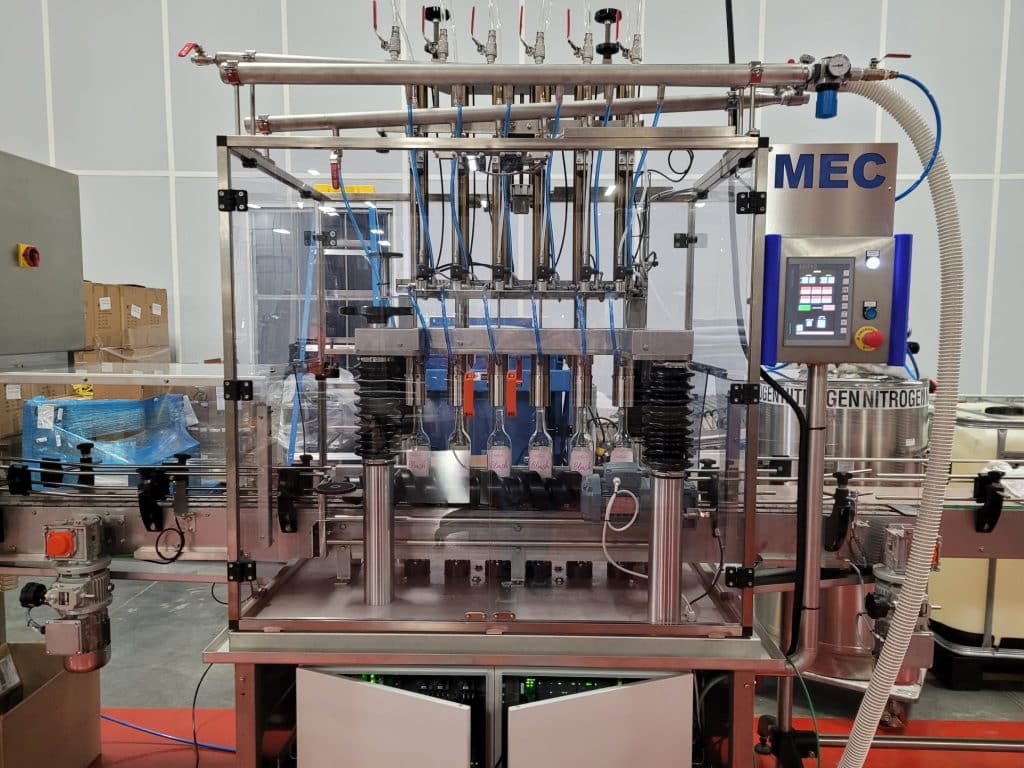

A linear system generating considerable space savings

Different bottle sizes

A machine capable of handling different bottle sizes. It can handle bottles from half-size (37.5 cl) to a magnum (150 cl)

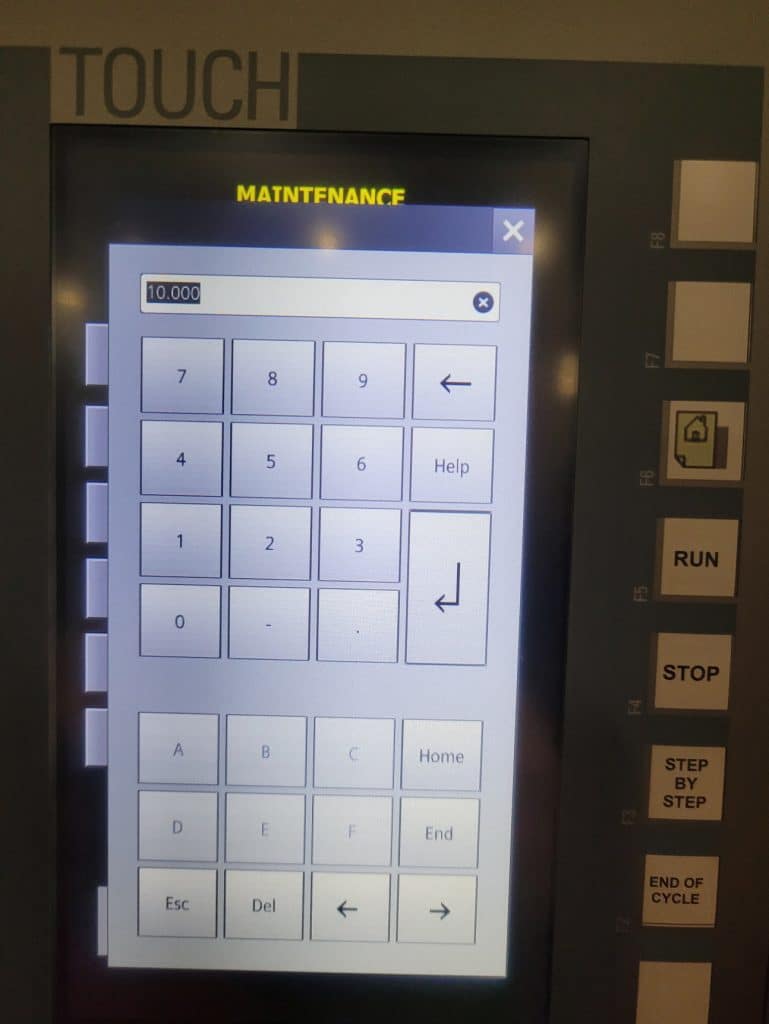

Simple and automated

The capacity to change the container for still or sparking wines. The transvasor extensively simplifies and automates operations in relation to other machines.

Safe washing

Predisposed for CIP machine washing, with dummy bottles used each time. The wash cycle is done in a closed loop.